Pre Insulated HVAC DUCT Panels

Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

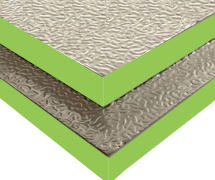

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

Recommended thickness for INDOOR application: 20mm

Recommended thickness for OUTDOOR application: 30mm

MA-01

PIR Panel with 45kg/m3 density, coated with 80/80µm thick embossed Al foil both sides

PIR80E20 - 20mm Thick

PIR80E30 - 30mm Thick

MA-02

PUR Panel with 45kg/m3 density, coated with 80/80µm thick embossed Al foil both sides

PUR80E20 - 20mm Thick

PUR80E30 - 30mm Thick

MA-03

Phenolic Panel with 55-60kg/m3 density, coated with 80/80µm thick embossed Al foil both sides

PHE80E20 - 20mm Thick

PHE80E30 - 30mm Thick

MA-04

PIR & PUR Panel with 50kg/m3 density, coated with 80/200µm thick embossed Al foil both sides

PIU80E20 - 20mm Thick

PIU80E30 - 30mm Thick

MA-05

Smooth Foam Panel with 45kg/m3 density, coated with 80/80µm thick embossed Al foil both sides

SFP80E20 - 20mm Thick

SFP80E30 - 30mm Thick

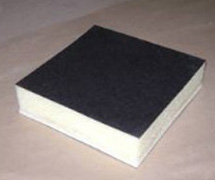

PURAPB50

PUR Panel of 50 mm thickness with both side Asphalt paper

PURKPB50

PUR Panel of 50 mm thickness with both side Kraft paper

PURGWB50

PUR Panel of 50 mm thickness with both side Glass wool

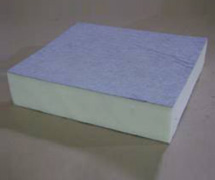

Thermal Insulation Board

Our panel can be easily and effectively applied to the insides of roofs and walls as well as for floor insulation. The seamless foam layer follows all the contours of the surface and sticks to all kinds of materials and surfaces. PIR insulation protects against cold, heat, damp and draughts. It is the perfect insulation.

Roof insulation:

Just like the inside of a roof, you can have the outside of a roof insulated. PIR insulating foam can be applied to both existing roofs and new roofs to prevent damage by sun, wind, and rain.

Wall insulation:

It can be done quickly and effective using PIR foam. The PIR foam sticks easily to any surface and follows all the contours, of in this case, the gable closely. There’s no chance of cold bridges.

Floor Insulation:

PIR foam has exceptionally good insulating and damp-proofing characteristics. The polyurethane is applied seamlessly against the underside of the floor of the ground floor, around floor boards and up to a certain height on the foundation joints. The result is a perfect separation between the climate in the crawlspace and that in the living room.

PIR foam panels can also be used to seamlessly seal the floor, in contrast to systems that seal off the ground. Homes, offices, etc with an acceptable humidity level indoors can benefit greatly by saving on energy bills using insulation.